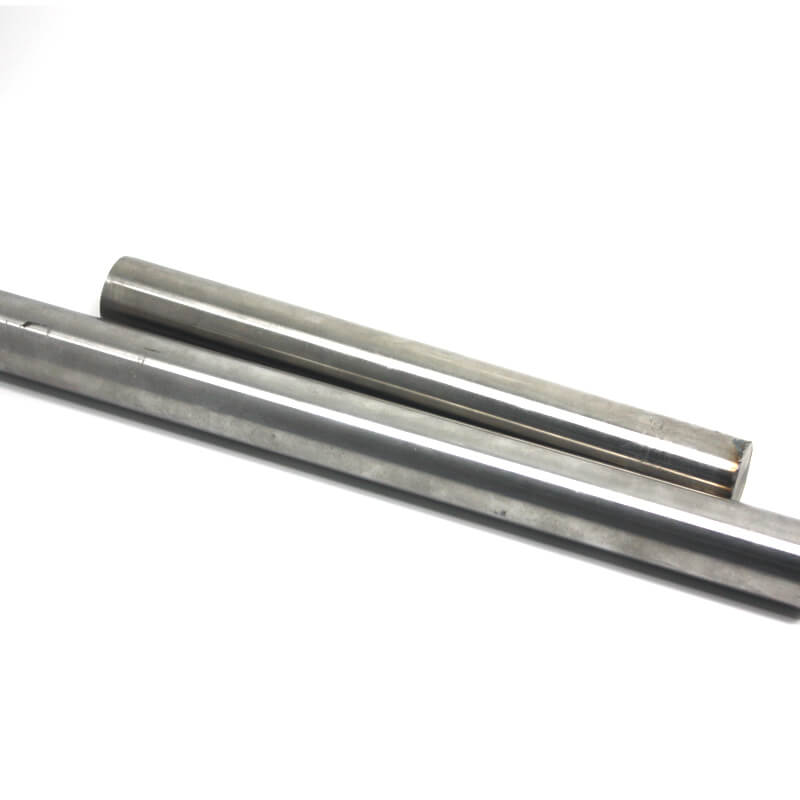

Jiangsu Bealloy Co.,Ltd produce special alloy products, including Bar, Rod, Sheet, Plate, Pipe, Tube, Pipe Fittings, Rings, Forgings, Flange, Coil and Strip, etc. If any requirements not found, please email us sales@bealloy.com. We will offer you best price and more details. Any customizationare accepted.

40CrNi2Mo is one of the alloy structural steels, also called alloy steels, on the basis of high quality carbon structural steel, it is made by properly adding one or several alloy elements (the total content is not more than 5%). After heat treatment bearing parts common quality defects are: hardened microstructure overheating, underheating, quenching cracks, insufficient hardness, heat distortion, surface decarburization, soft points.

Implementation standards: GB / T 3077-2015

|

C |

Si |

Mn |

S |

P |

Cr |

Ni |

Cu |

Mo |

|

0.37 - 0.45 |

0.15 - 0.35 |

0.50 - 0.80 |

max 0.030 |

max 0.025 |

0.60 - 0.90 |

1.25 - 1.65 |

Max 0.025 |

0.15 - 0.25 |

|

Tensile strength σb (MPa) |

≥980(100) |

|

Yield strength σs (MPa) |

≥835(85) |

|

Elongation δ5 (%) |

≥12 |

|

Section shrinkage rate ψ (%) |

≥55 |

|

Impact work Akv (J) |

≥78 |

|

Impact toughness value αkv (J / cm2) |

≥98 (10) |

|

Hardness (HB) |

≤269 |

In what applications is 40CrNi2Mo used?

40CrNi2Mo is widely used in ships, vehicles, aircraft, missiles, weapons, railways, bridges, pressure vessels, machine tools and other structures.

Heat treatment specifications

Quenching at 850 ° C, oil cooling; tempering at 600 ° C, water cooling, oil cooling.

Delivery status

Delivery in heat treatment (normalizing, annealing or high temperature tempering) or non heat treatment state, which shall be indicated in the contract.

- Nickel Based Alloys

-

Super Special Stainless

- Duplex 2205/ S31803/1.4462/F51

- Duplex 2507 / S32750 / 1.4410 /F53

- Duplex S32760 / 1.4501 / F55

- 904L / UNS N08904 / 1.4539

- 253 MA / S30815 / 1.4835

- 254 SMO / S31254 /1.4547

- 17-4PH / AISI630 / 1.4542

- AISI 316Ti / 1.4571

- 317L Stainless Steel

- AISI 310MOLN / 1.4466 Stainless Steel

- 347/347H 1.4550 Stainless Steel

- UNS N08367 / AL-6XN® / 1.4529

- Stainless Steel

- Alloy Steel

- TITANIUM AND TITANIUM ALLOYS