|

美标牌号 ASTM/ASME Grade |

其他标号 Other Name |

欧标代码 EN Grade |

Chemical Component % | ||||||||||||

| C | Cr | Ni | Mn | P | S | Si | Cu | W | MO | V | CO | B | |||

| 17CrNiMo6 | EN10084 | 0.14-0.19 | 1.5-1.8 | 1.4-1.7 | 0.4-0.6 | 0.03 | 0.03 | 0.17-0.35 | 0.25 | 0.25-0.35 | |||||

| 34CrNiMo6 | 1.6582 | 0.34 | 1.5 | 1.55 | 0.5 | 0.25-0.3 | 0.2 | ||||||||

| 30CrNi3 | 30CrNiMo8 | 0.26-0.34 | 1.8-2.2 | 1.8-2.2 | 0.5-0.8 | 0.025 | 0.035 | 0.4 | 0.3-0.5 | ||||||

| 16MnCr5 | 1.7131 | 0.14-0.19 | 0.8-1.1 | 1.0-1.3 | 0.035 | 0.035 | 0.4 | ||||||||

| 20MnCr5 | 0.17-0.22 | 1.0-1.3 | 1.1-1.5 | 0.035 | 0.01-0.035 | 0.25 | |||||||||

| 20CrMnMo | SCM421 | 0.17-0.32 | 1.1-1.4 | 0.03 | 0.9-1.2 | 0.17-0.37 | 0.03 | 0.2-0.3 | |||||||

| 4142 | 40CrMnMo | 1.7225 | 0.37-0.45 | 0.9-1.2 | 0.9-1.2 | 0.17-0.37 | 0.2-0.3 | ||||||||

| 20CrMnSi | 0.17-0.23 | 0.8-1.1 | 0.03 | 0.8-1.1 | 0.035 | 0.035 | 0.9-1.2 | 0.03 | |||||||

| 35CrMnSi | 0.32-0.39 | 1.1-1.4 | 0.03 | 0.8-1.1 | 0.025 | 0.025 | 0.025 | ||||||||

| 18Cr2Ni4WA | 0.13-0.19 | 1.35-1.65 | 4-4.5 | 0.3-0.6 | 0.025 | 0.025 | 0.17-0.37 | 0.025 | 0.8-1.2 | ||||||

| 25Cr2Ni4WA | 0.21-0.28 | 1.35-1.65 | 4-4.5 | 0.3-0.6 | 0.025 | 0.025 | 0.17-0.37 | 0.025 | 0.8-1.2 | ||||||

| 20CrNiMoA | 0.17-0.23 | 0.4-0.7 | 0.35-0.75 | 0.6-0.95 | 0.035 | 0.035 | 0.17-0.37 | 0.03 | 0.2-0.3 | ||||||

| 4340 | 40CrNiMoA | 0.37-0.44 | 0.6-0.9 | 1.25-1.65 | 0.5-0.8 | 0.025 | 0.025 | 0.17-0.37 | 0.25 | 0.15-0.25 | |||||

| 12CrNi3 | 1.5752 | 0.1-0.17 | 0.6-0.9 | 2.75-3.15 | 0.3-0.6 | 0.035 | 0.035 | 0.17-0.37 | 0.03 | ||||||

| 37CrNi3 | 0.34-0.41 | 1.2-1.6 | 3-3.5 | 0.3-0.6 | 0.17-0.37 | ||||||||||

| 34CrNi3Mo | 0.3-0.4 | 0.7-1.1 | 2.75-3.25 | 0.5-0.8 | 0.035 | 0.035 | 0.17-0.37 | 0.2 | 0.25-0.4 | ||||||

| 25Cr2MoV | 0.22-0.29 | 1.5-1.8 | 0.4-0.7 | 0.035 | 0.035 | 0.17-0.37 | 0.25-0.35 | 0.15-0.3 | |||||||

| 40CrNi2Mo | 0.37-0.45 | 0.6-0.9 | 1.25-1.65 | 0.5-0.8 | 0.025 | 0.03 | 0.15-0.35 | 0.025 | 0.15-0.25 | ||||||

| 4340 | 40CrNiMo | 0.38-0.43 | 0.7-0.9 | 1.65-2 | 0.6-0.8 | 0.035 | 0.04 | 0.15-0.35 | 0.2-0.3 | ||||||

| 35CrMoV | 0.3-0.38 | 1-1.3 | 0.03 | 0.4-0.7 | 0.035 | 0.035 | 0.17-0.37 | 0.025 | 0.2-0.3 | 0.1-0.2 | |||||

| 4Cr5MoSiV1 | H13 | 0.32-0.45 | 4.75-5.5 | 0.2-0.5 | 0.03 | 0.03 | 0.8-1.2 | 1.1-1.75 | 0.8-1.2 | ||||||

| 31CrMoV9 | 0.27-0.34 | 2.3-2.7 | 0.4-0.7 | 0.025 | 0.035 | 0.4 | 0.15-0.25 | 0.1-0.2 | |||||||

| 50CrV4 | DIN17221 | 0.46-0.54 | 0.8-1.1 | 0.35 | 0.5-0.8 | 0.03 | 0.03 | 0.17-0.37 | 0.25 | 0.1-0.2 | |||||

| 50CrNi | 0.47-0.54 | 0.45-0.75 | 1-1.4 | 0.5-0.8 | 0.035 | 0.035 | 0.17-0.37 | 0.03 | |||||||

| 5140 | 40Cr | 1.7035 | 0.37-0.44 | 0.8-1.1 | 0.3 | 0.5-0.8 | 0.035 | 0.035 | 0.17-0.37 | 0.03 | 0.1 | ||||

| 5CrMnMo | 0.5-0.6 | 0.6-0.9 | 0.25 | 1.2-1.6 | 0.03 | 0.03 | 0.25-0.6 | 0.3 | 0.15-0.3 | ||||||

| 20Cr2Ni4A | 0.17-0.23 | 1.25-1.65 | 3.25-3.65 | 0.3-0.6 | 0.03 | 0.03 | 0.17-0.37 | ||||||||

| 12Cr1MoV | 0.08-0.15 | 0.9-1.2 | 0.4-0.7 | 0.17-0.37 | 0.25-0.35 | 0.15-0.3 | |||||||||

| 15CrNi3Mo | 0.13-0.18 | 0.9-1.2 | 2.6-3 | 0.3-0.6 | 0.02 | 0.015 | 0.17-0.37 | 0.25 | 0.2-0.27 | 0.03-0.08 | |||||

| 23CrNi3Mo | 0.2-0.27 | 1.1-1.5 | 2.75-3.25 | 0.55-0.85 | 0.025 | 0.025 | 0.15-0.35 | 0.2 | 0.2-0.3 | ||||||

| 42CrMov | 35SiMn | 1.5122 | 0.32-0.4 | 0.3 | 0.3 | 1.1-1.4 | 0.35 | 0.35 | 1.1-1.4 | 0.3 | |||||

| 9260 | 60Si2MnA | 0.54-0.6 | 0.35 | 0.35 | 0.7-1.0 | 0.035 | 0.035 | 1.5-2 | 0.25 | 0.08-0.16 | 0.0005~0.0035 | ||||

| 1566 | 65Mn | 0.62-0.7 | 0.025 | 0.025 | 0.9-1.2 | 0.035 | 0.035 | 0.17-0.37 | 0.025 | ||||||

| 55Cr3 | DIN17221 | 0.52-0.6 | 0.65-0.95 | 0.35 | 0.65-0.95 | 0.03 | 0.03 | 0.17-0.37 | 0.25 | 0.1-0.2 | |||||

| 60Cr3 | 0.56-0.64 | 0.7-1.0 | 0.35 | 0.7-1.0 | 0.03 | 0.03 | 0.17-0.37 | 0.25 | |||||||

| UNS G61500 | 51CrV4 | 1.8159 | 0.47-0.55 | 0.9-1.2 | 0.35 | 0.7-1.1 | 0.03 | 0.03 | 0.4 | 0.25 | 0.1-0.25 | ||||

| 12Cr2Mo1R | 0.08-0.15 | 2-2.5 | 0.3-0.6 | 0.02 | 0.01 | 0.5 | 0.9-1.1 | ||||||||

| 15CrMo | 0.12-0.18 | 0.8-1.1 | 0.3 | 0.4-0.7 | 0.035 | 0.035 | 0.17-0.37 | 0.4-0.55 | |||||||

| 27SiMn | 0.24-0.32 | 0.3 | 0.3 | 1.1-1.4 | 0.035 | 0.035 | 1.1-1.4 | 0.3 | 0.15 | ||||||

| 42CrMov | 35SiMn | 1.5122 | 0.32-0.4 | 0.3 | 0.3 | 1.1-1.4 | 0.35 | 0.35 | 1.1-1.4 | 0.3 | |||||

| 1Cr5Mo | 0.15 | 4.0-6.0 | 0.6 | 0.6 | 0.03 | 0.02 | 0.5 | 0.45-0.6 | |||||||

| 55SiCrA | 0.51-0.59 | 0.5-1.0 | 0.35 | 0.5-0.8 | 0.025 | 0.025 | 1.2-1.6 | 0.25 | |||||||

| 60Si2CrA | 0.56-0.64 | 0.7-1.0 | 0.35 | 0.4-0.7 | 0.03 | 0.03 | 1.4-1.8 | 0.25 | |||||||

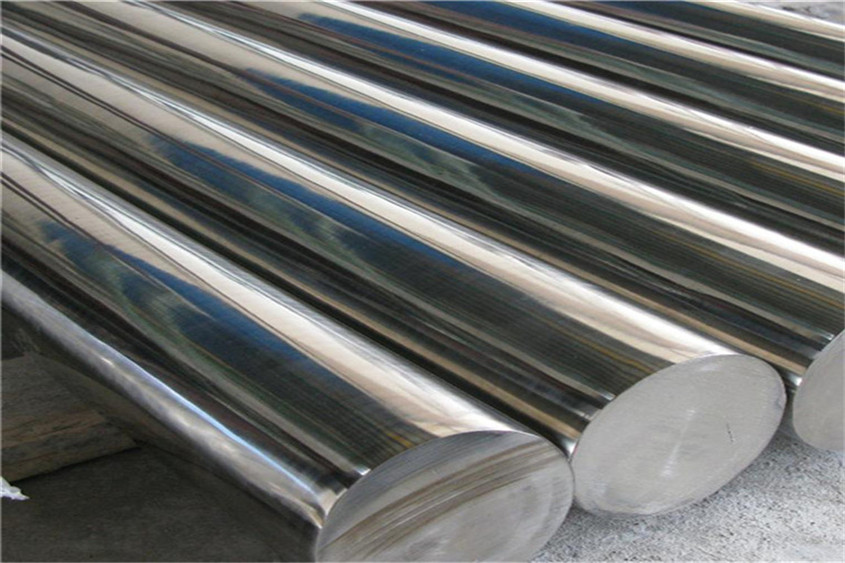

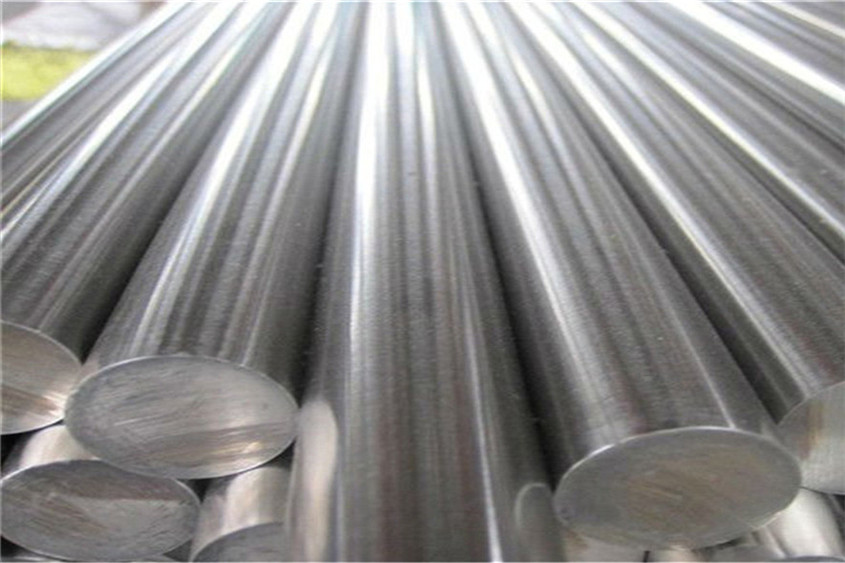

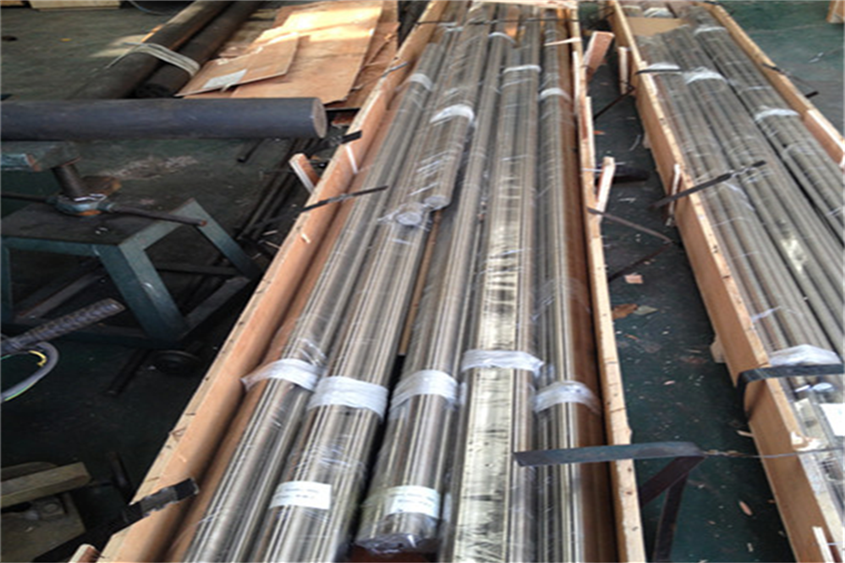

Alloy bars generally have the shapes such as flat, round, hexagonal, square and channel and on most of the occasions, it is the shape of the bar that defines its application area.It can be categorically said that steel bars are one of the core components of any manufacturing industry or for that matter any industry that relies on machineries.

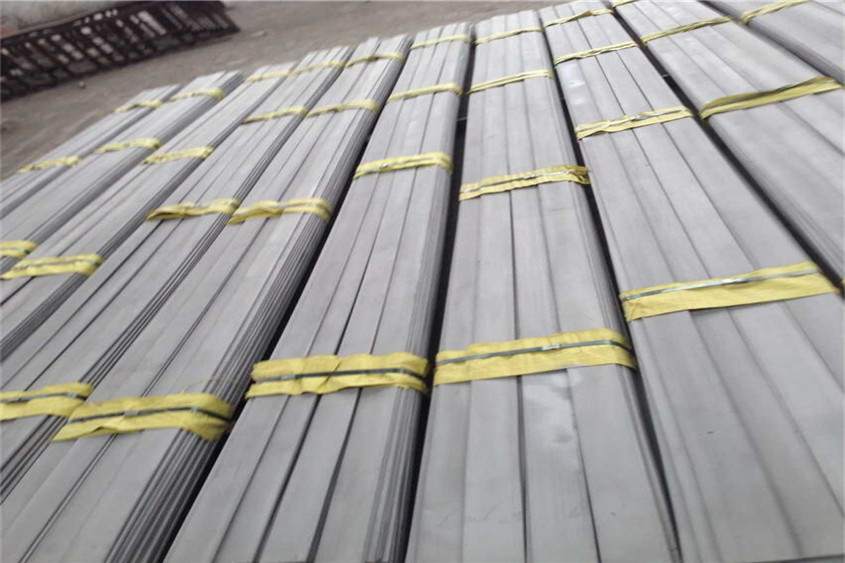

Flat bar: Most of the flat bars find it application in construction industries in the form of base plates and brackets

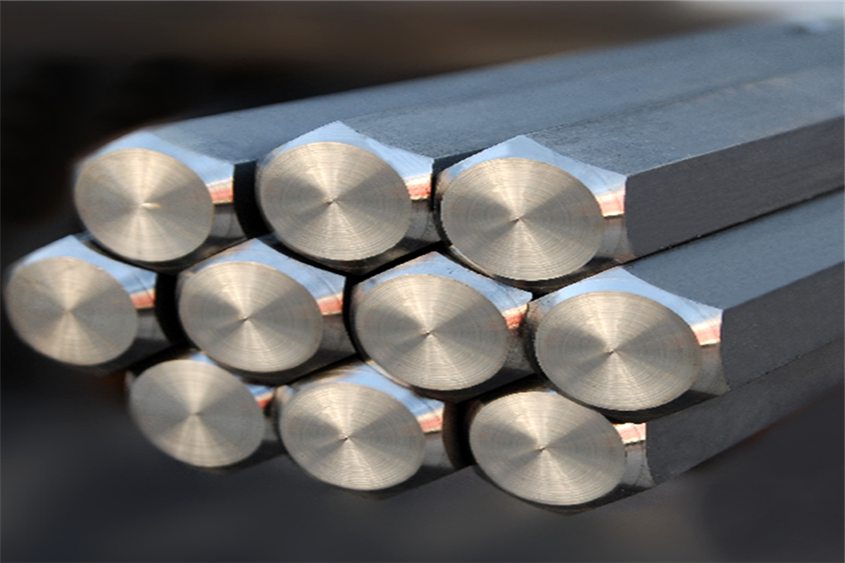

Hexagonal bars: These weight bearing bars have their end use in construction industries with the possibility of tailor made sizes. It can be used as bridge, frame, fence, transmission ship, vehicle, fasteners etc..

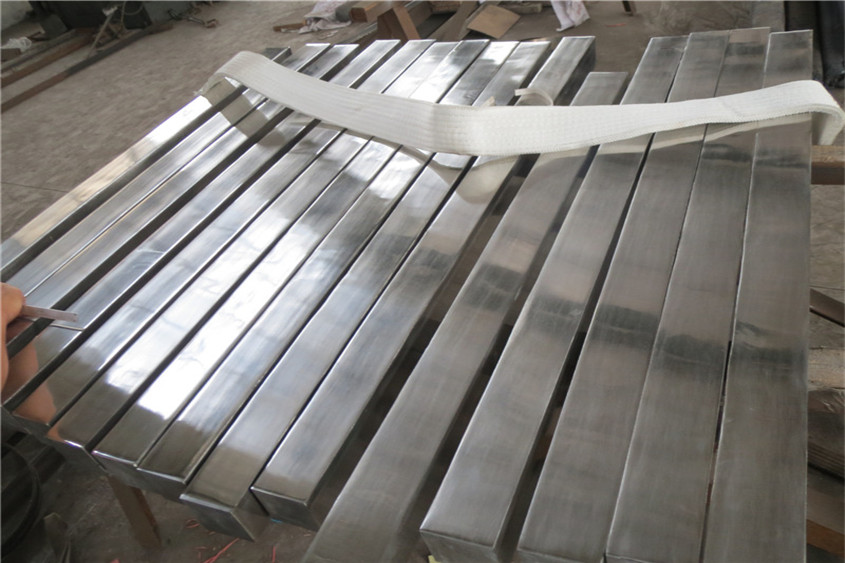

Square bars: These are again from one of the popular categories that enjoy wide application in manufacturing industry pertaining to machineries, fasteners, and equipments.

Angle bars: angle bar is corrosion resistant and provides good mechanical properties, it’s used in the fabrication of I beams, H beams, C beams or any other major structural material, which makes it ideal for construction projects.

-

Bundle

-

Wooden Box

-

Flat

-

Wooden Case

-

Forging

-

UT

-

Cutting

-

Maching

- Nickel Based Alloys

-

Super Special Stainless

- Duplex 2205/ S31803/1.4462/F51

- Duplex 2507 / S32750 / 1.4410 /F53

- Duplex S32760 / 1.4501 / F55

- 904L / UNS N08904 / 1.4539

- 253 MA / S30815 / 1.4835

- 254 SMO / S31254 /1.4547

- 17-4PH / AISI630 / 1.4542

- AISI 316Ti / 1.4571

- 317L Stainless Steel

- AISI 310MOLN / 1.4466 Stainless Steel

- 347/347H 1.4550 Stainless Steel

- UNS N08367 / AL-6XN® / 1.4529

- Stainless Steel

- Alloy Steel

- TITANIUM AND TITANIUM ALLOYS